Machines At a glance

Our products are as versatile as yours – and therefore as flexible as you need them to be.

The A&D modular system enables individual solutions that are easy to configure.

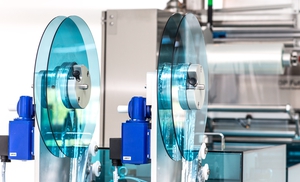

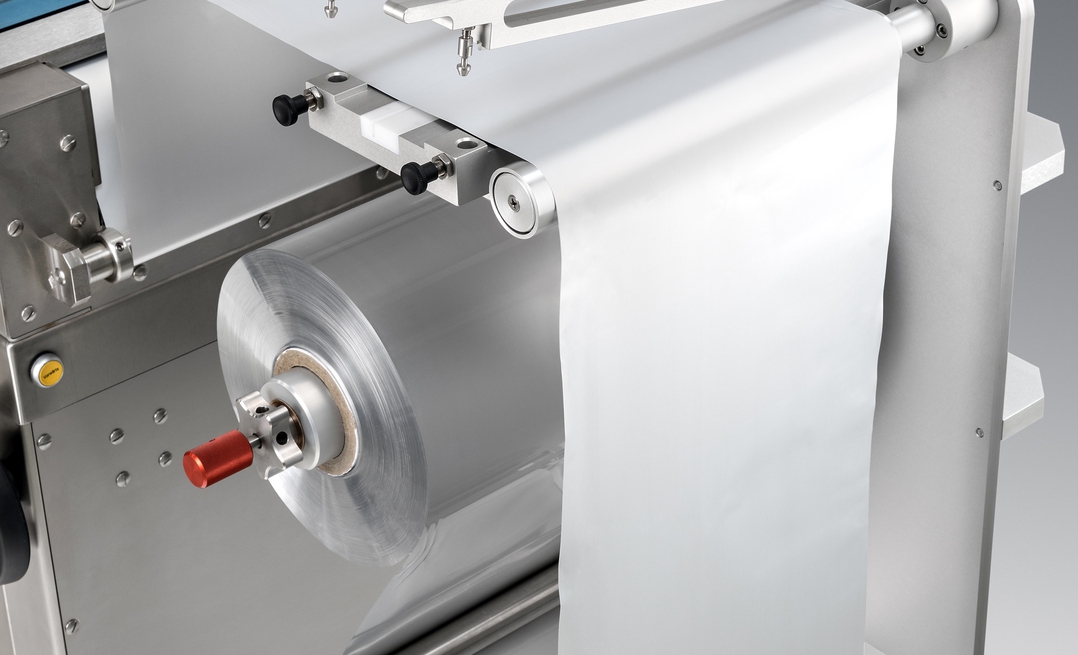

Thermoformer

FFS-S

Innovative, powerful, mature:

A perfect generalist.

A perfect generalist.

The FFS-S is a thermoform machine fulfilling highest demands as well as accounting for a great variety of customer requirements.

The FFS-S is equipped with highest-quality components even in its basic configuration. Its frame’s stability is preeminent, providing the basis for a durable machine.

- According to your requirements, the FFS-S can be supplemented by numerous stations. Jumbo-rolls receiver, cutting and splicing tables and a multitude of cleaning, cutting and packing devices make the FFS-S a real all-round talent.

- Frame: Stainless steel

- Cover panel: Stainless steel

- Film widths: 185 – 600 mm (5 mm gradation)

- Repeat length: 60 – 1200 mm

- Deep-draw: up to 190 mm

- Film material: hard and flexible film

- Control unit: Siemens S7

- Operator panel: Pro-Face TFT Touch Panel 10‘‘

- Pneumatic system: Festo

- Film transportation: two-way clamping chain 5,8“

- Lower film reception: Ø 600 mm

- Upper film reception: Ø 400 mm

- Lifting station: pneumatic with bell-crank lever

- Transverse and longitudinal cutting

- Strip scrap: rewind with diagnostic error system

- Advance warning film end

- Film end recognition

- Splice recognition

- Print mark control outer web

- Cut and splice table

- Multi-foil heating

- Positive shaping

- Stamp pre-stretch

- Printer for top web printing

- Vacuum and gas supply panel

- Take-Off sealing station

- Cutting station

- Automatic product infeed

- Filler for liquid and pasty products

- Automatic packaging re-stacker

- Lifting stations: pneumatic, pneumo-hydraulic, electromechanic, etc.

- Alternative control

- Alternative operator panel

- Knee-free loading zone

- Final packaging solutions

- Integration into production systems

- Interface coordination

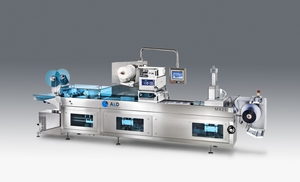

Thermoformer

M-SYSTEM

Flexible, Compact, Competitive:

A convincing solution.

A convincing solution.

Customers looking for an efficient and economic facility providing a wide range of applications will find the M-System the perfect solution. Thanks to its minimal space requirement, the machine is easily integrated in almost every environment. Its high flexibility enables fast and simple adjustments to current production demands.

- M100 The compact basic model is optimally suited for less complex applications.

- M110 The M100’s upgrade with a footprint smaller than 3 m² is based on a modular system and can be easily extended.

- M285 The all-round model for the medium performance range impresses with its favourable price.

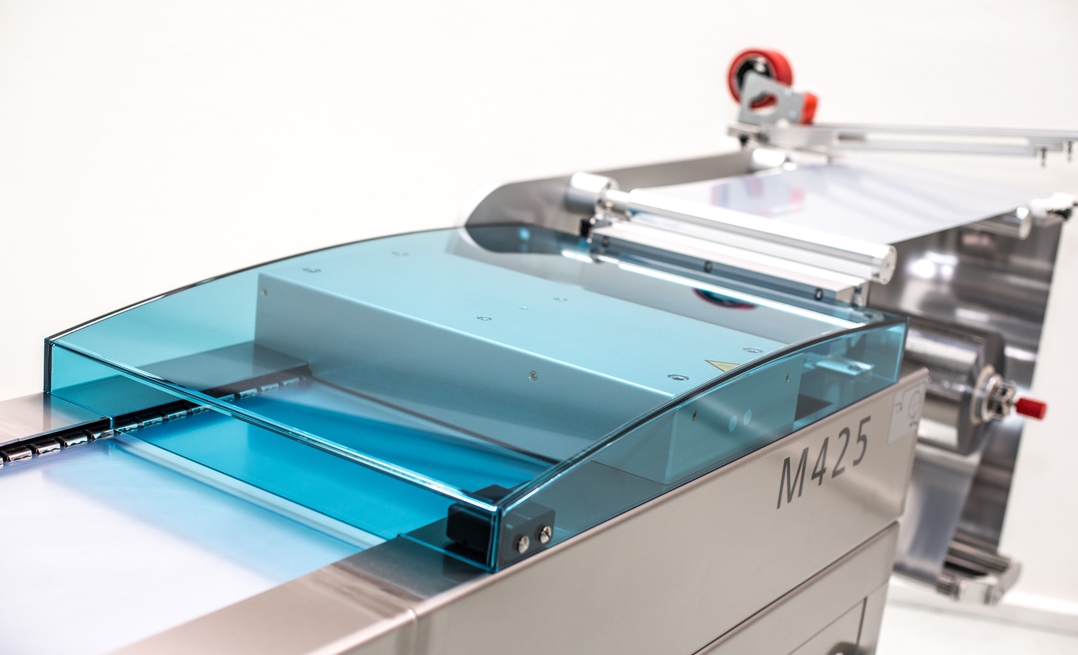

- M425 The premium edition meets highest requirements in the upper performance range.

Exemplary for M425.

- Film widths: 250, 285, 320, 355, 420, 460 mm

- Repeat length: up to 400 mm

- Control unit: S7-300 with TFT Touch-Panel 10’ operating board on swivel arm

- Drive: servomotor

- Sealing: frame sealing

- Film end control for bottom and top web

- Strip scrap rewinder on both sides, with diagnostic error system

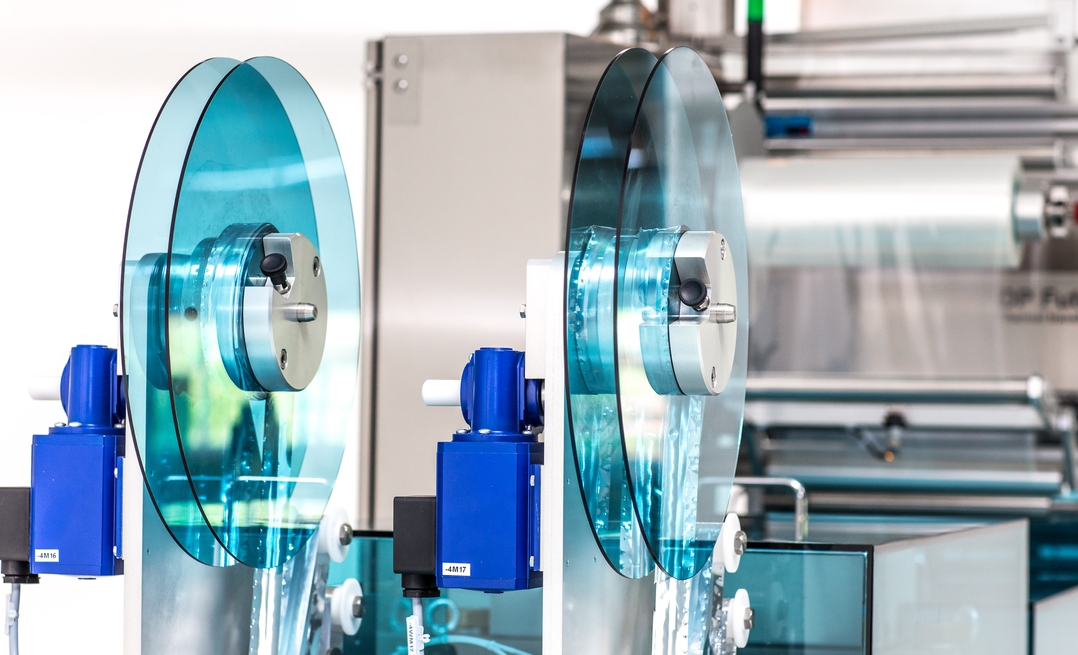

- Water chiller

- Vacuum and gas flush unit

- Direct printing of top web with

- Thermal transfer printer

- Flexo printer

- Ink-jet printer

- Advance warning film end bottom and top web

- Film end control bottom and top web

- Die-cut station

- Packing transfer unit

- Automatic product infeed system

- Quality assurance inline

- OCR recognition

- Inscription check

- Infeed robot

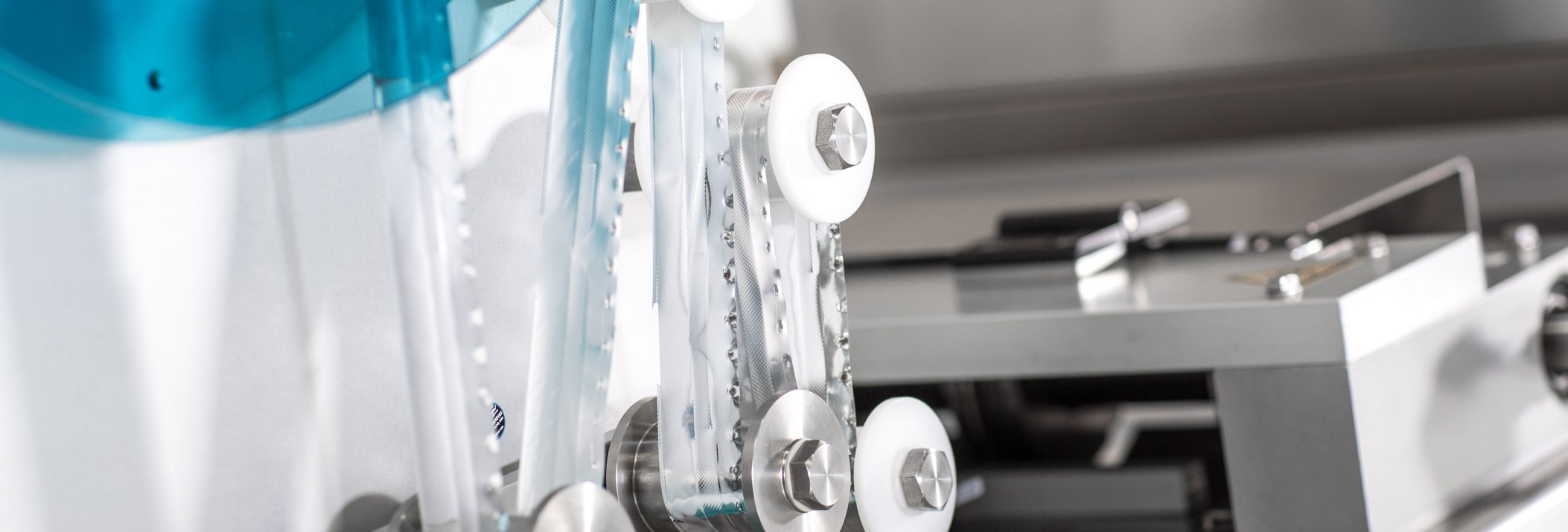

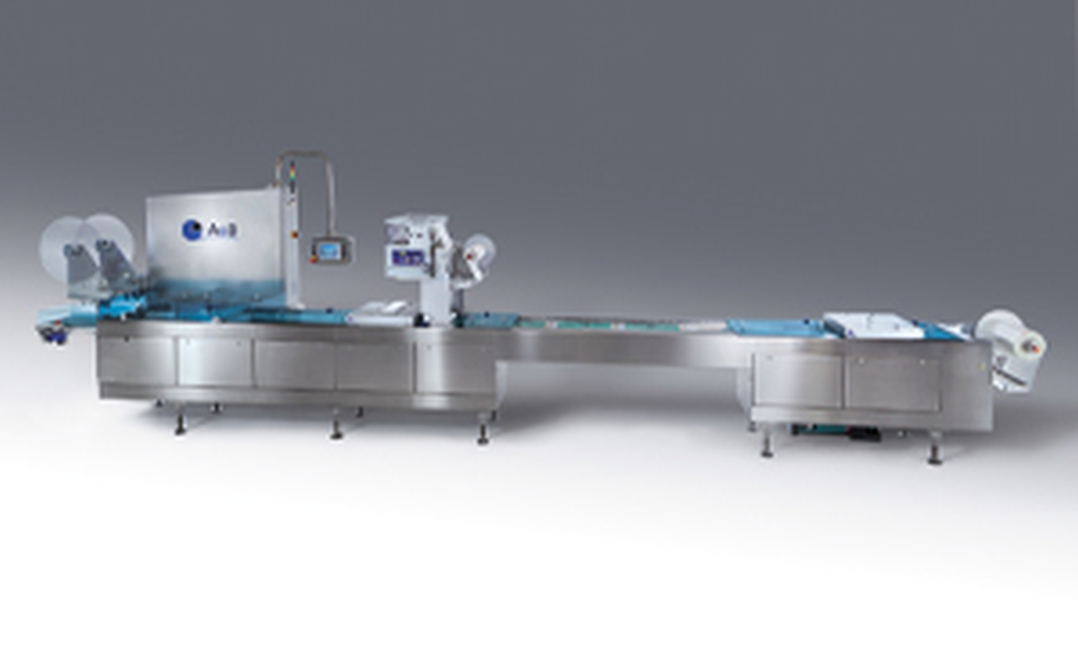

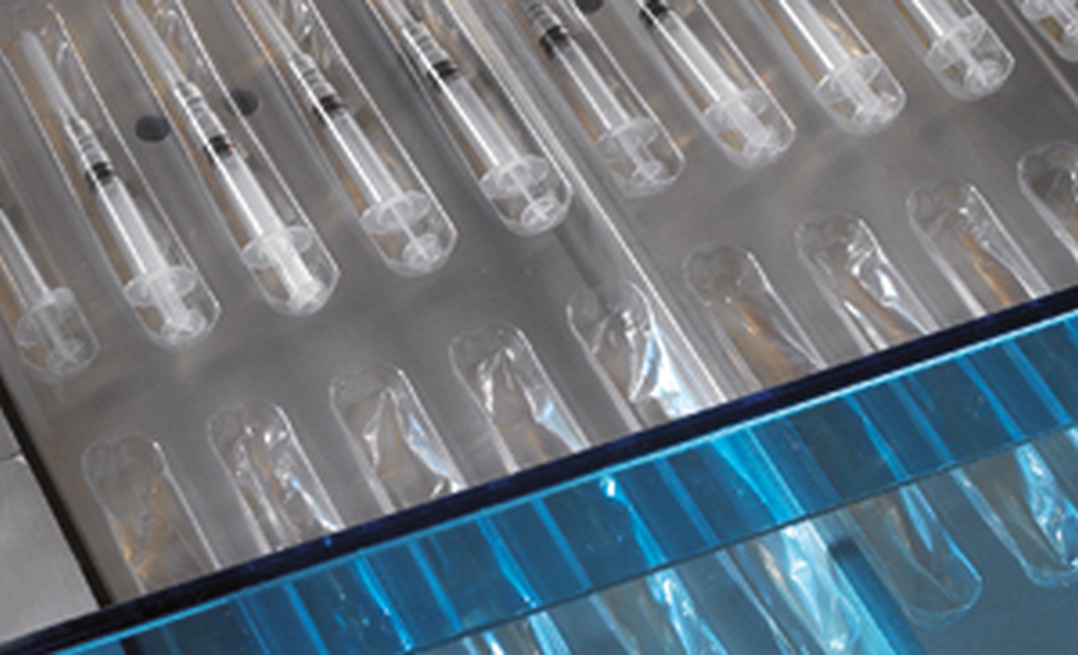

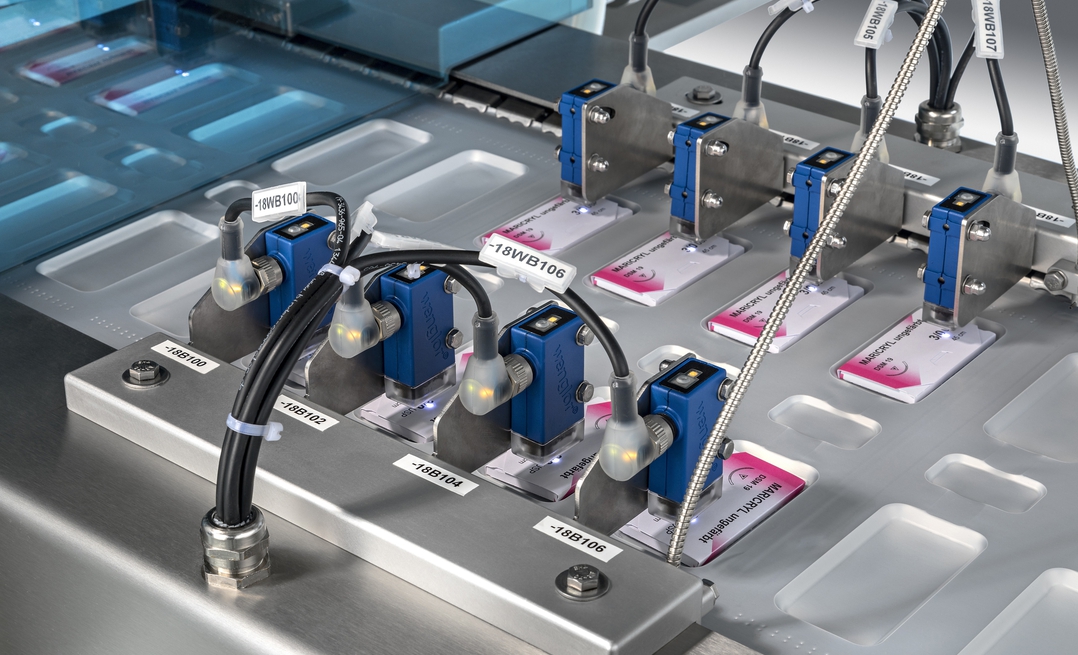

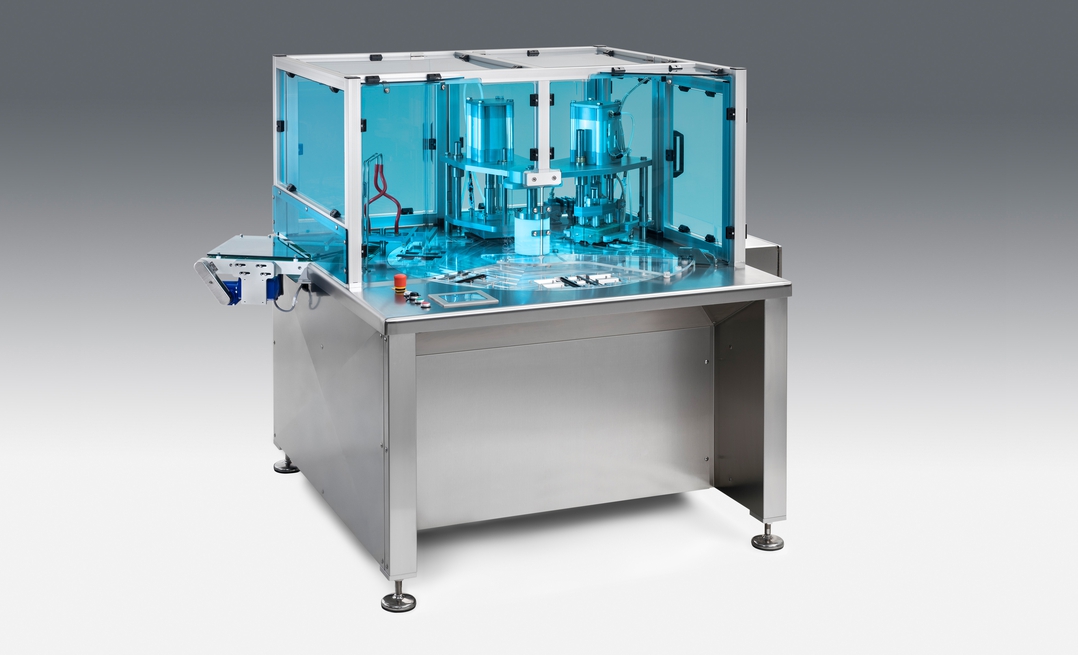

Sutures Packaging System

PGA

For efficient processes resulting

In safe products.

In safe products.

Customers looking for an efficient and economic facility will find this packaging line for PGA blisters a highly productive solution.

This packaging system is especially easy to handle and highly economical, allowing you to benefit from short lead times throughout the whole process.

Thanks to its minimal space requirement, the machine is easily integrated in almost every environment. Its high flexibility enables fast and simple adjustments to current production demands.

- Inline sterile window application

- Knee-free loading area

- 80 packs/min

- Final OK/NOK handling

- Inline product control

- Control unit: S7-300 with TFT Touch-Panel

- 10’’ operating board on swivel arm

- Drive: servomotor

- Sealing: frame sealing

- Packing transfer unit

- Water chiller

- Direct printing of top web with

- Thermal transfer printer

- Digital printer

- Ink-jet printer

- Advance warning film end bottom and top web

- Film end control bottom and top web

- Pin hole detection

- Labelling

- Automatic product infeed system

- Infeed robot

- Inline quality inspection

- OCR recognition

- Inscripition check

- Web guide control

- Sticker mark control

- Cutting and splicing table

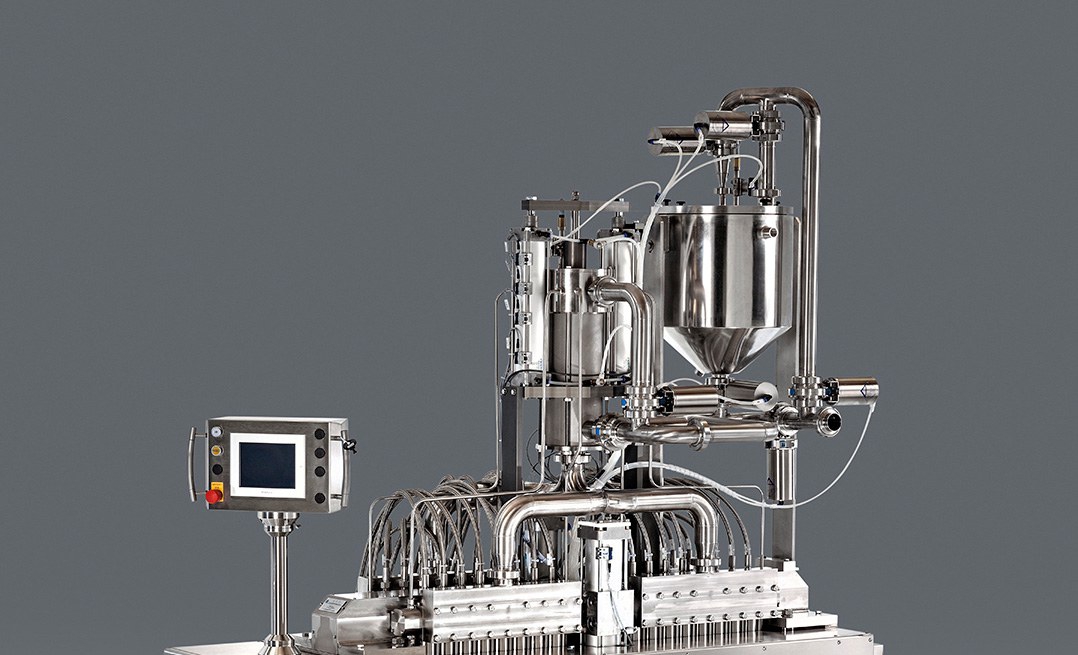

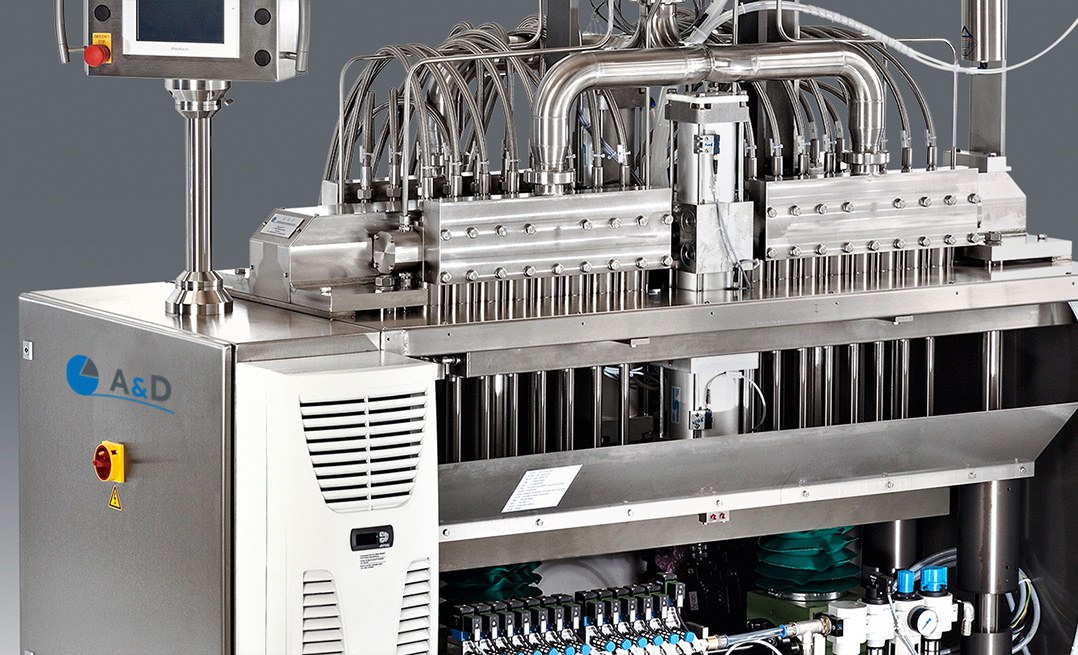

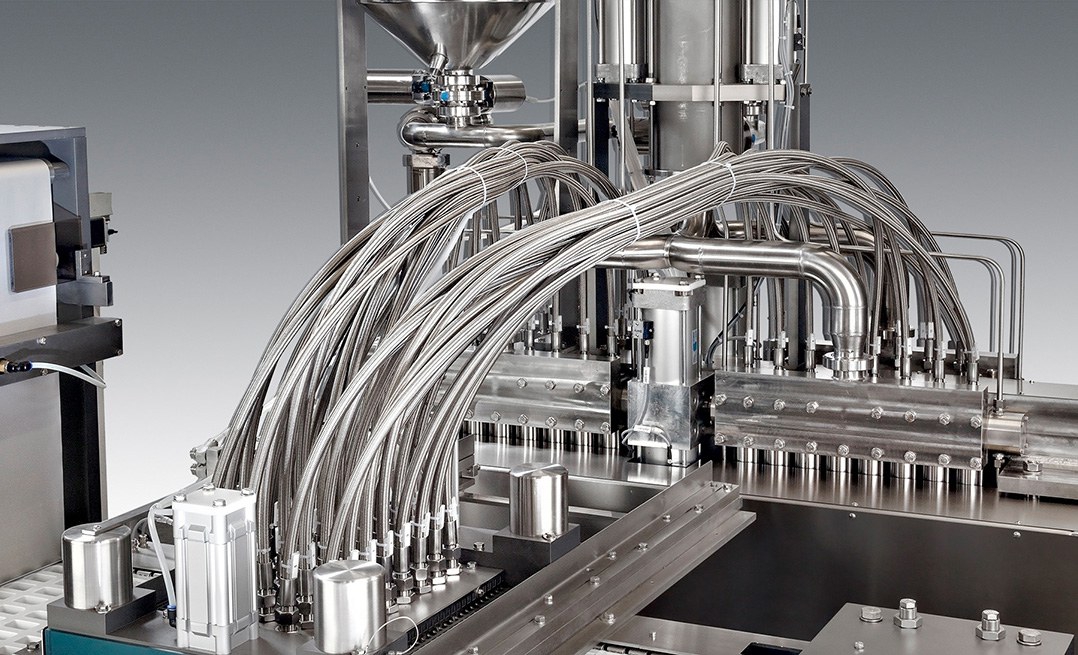

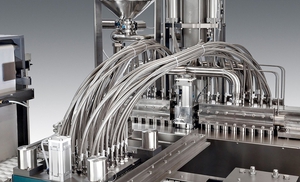

Filler

KF

Precise dosing,

flexible in use.

flexible in use.

Modular design, up to 32 dosage units.

Versatile use for liquid and pasty products.

Examples: Natural yoghurt, fruit yoghurt, cottage cheese, soft cheese, curd cheese, cream cheese, honey, jam, butter, margarine, mayonnaise, ketchup, etc.

- 8, 12, 16, 24 or 32 dosing units

- Dosing capacity from 10 to 500 ml

- filling accuracy: +/- 0,5% per cycle

- Maximum product temperature: 80° C

- Up to 4 products can be processed simultaneously

- Compensator and / or filling hopper

- Filling nozzle plate

- CIP programs / CIP valves

- Non-drip filling nozzles

- Reverse suction for liquid products

- Clear arrangement and good accessibility

- Refittable as add-on filler

- Control: Simens S7

- Server drive

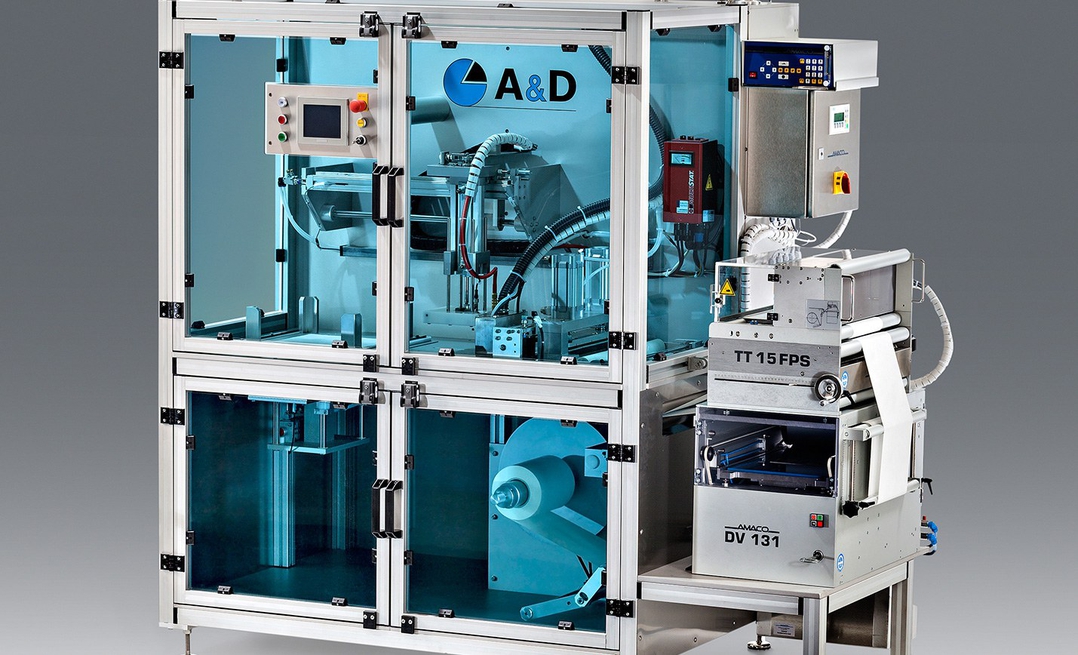

Special

Machines

Your requirements are

exceptionally special?

We will find a solution!

exceptionally special?

We will find a solution!

Special machines from A&D are systems that are directly related to our core competencies, which include forming, filling, cutting, sealing, stamping and handling, or used in direct connection with our thermoforming machines.

These systems are exactly designed and built according to customer specifications. All automated systems at A&D are standardly equipped with a Siemens PLC and thus draw on the simple and proven HMI.

It goes without saying that our special machines have the same ruggedness, reliability and high quality as our thermoforming machines.

- Cutting and Sealing Machine

- Cutter for Sealing Layers

- Chamber Machine K400 / DK400